What Is Graphene Coating?

Graphene coating is an advanced surface protection technology that uses graphene-based materials in a coating formula to improve durability, water repellency, and resistance to environmental wear. In commercial products, this usually does not mean a perfect single-atom graphene sheet covering a surface. Instead, it typically refers to a graphene-enhanced coating system designed to improve performance compared with conventional formulas.

Because graphene-related materials can contribute strength, conductivity, and barrier properties, graphene coating has gained attention in automotive detailing, electronics protection, and industrial anti-corrosion applications. The main appeal is not just shine, but longer-lasting protection and easier maintenance when the product is properly applied.

If you want a broader overview of the material behind this trend, see our guide on what graphene is and why it matters.

How Does Graphene Coating Work?

At a practical level, a graphene coating works by forming a thin protective layer over a surface. This layer helps reduce direct exposure to moisture, contaminants, UV radiation, and chemical residues. In many products, graphene-based additives are blended with resins or ceramic-like components to improve coating behavior rather than acting alone.

Depending on the formulation, a graphene coating may help with:

- Water repellency (hydrophobic behavior), which helps water bead and roll off

- Contaminant resistance, which can make cleaning easier

- UV and chemical resistance, which may slow surface degradation

- Surface slickness, which can reduce dirt adhesion

- Durability support, especially in hybrid coating systems

Performance varies significantly by formula, surface preparation, and application quality. This is important because many “graphene coating” claims in the market describe the brand label more than the actual concentration or role of graphene in the product.

Key Applications of Graphene Coating

Automotive Paint Protection

One of the fastest-growing uses of graphene coating is automotive detailing. Graphene-based and graphene ceramic coating products are marketed for paint protection, gloss retention, hydrophobic behavior, and easier washing. When applied correctly over a properly prepared surface, they can help reduce contamination buildup and improve maintenance results.

It is worth staying realistic here: no coating makes paint scratch-proof. However, a quality graphene coating can improve resistance to environmental wear and make routine cleaning easier compared with unprotected paint.

Electronics and Technology

Graphene coating is also explored in electronics and technology applications where thin, lightweight protection matters. Coating systems may help protect components from moisture, oxidation, and corrosion without adding much bulk. This is relevant in sensors, wearables, flexible electronics, and specialized hardware exposed to demanding environments.

In advanced use cases, graphene-based materials are studied not only for protection but also for conductivity and thermal management, although commercial adoption depends on cost, manufacturability, and reliability.

Construction and Marine Protection

In construction and marine settings, protective coatings must withstand moisture, salt exposure, and harsh weather. Graphene-enhanced coatings are being evaluated for anti-corrosion and durability improvements on metals, concrete, and infrastructure surfaces. In marine applications, resistance to saltwater exposure is especially valuable because corrosion control directly affects maintenance cost and asset lifespan.

Adoption in these sectors depends on long-term field performance data, not just lab tests, so this remains a promising but application-specific area.

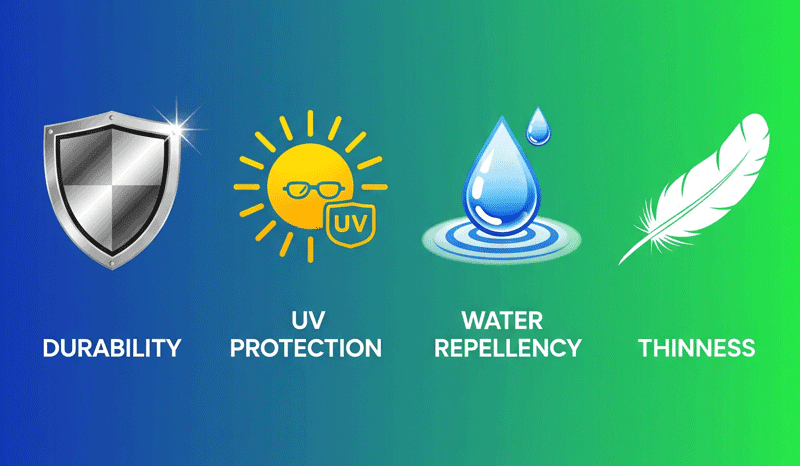

Advantages of Graphene Coating

When the formulation and application are good, graphene coating can offer several practical benefits:

- Durability support: Can improve long-term protection in graphene-enhanced or hybrid coating systems.

- Hydrophobic behavior: Helps water bead and reduces dirt adhesion, making surfaces easier to clean.

- Chemical and UV resistance: May slow fading, oxidation, and environmental wear.

- Thin protective layer: Adds minimal thickness and weight, useful for precision surfaces.

- Potential thermal benefits: Some formulations may support better heat distribution, depending on the application.

The key point is that results depend on the complete coating chemistry, not graphene alone. Surface prep, cure time, and maintenance habits can make a bigger difference than marketing labels.

Graphene Coating vs Ceramic Coating

A common question is whether graphene coating is better than ceramic coating. The honest answer is that it depends on the product formula and your use case. Many graphene products are actually hybrid coatings that combine ceramic components with graphene-based additives.

In general terms:

- Ceramic coatings are known for hardness, gloss, and chemical resistance.

- Graphene-enhanced coatings are often marketed for slickness, hydrophobicity, reduced water spotting, and improved durability characteristics.

- Hybrid graphene ceramic coating products aim to combine both sets of benefits.

Instead of assuming one category always wins, compare real-world performance data, durability claims, preparation requirements, and maintenance recommendations.

Graphene Ceramic Coating: Combining Strength and Durability

Graphene ceramic coating is a hybrid surface protection approach that combines ceramic coating chemistry with graphene-based additives. The goal is to improve durability, hydrophobic behavior, and surface resilience beyond what a basic coating formula can offer on its own.

In automotive detailing, graphene ceramic coating has become especially popular because users want strong paint protection with easier cleaning and long-lasting gloss. Depending on the formula, these coatings may offer better slickness, improved contaminant resistance, and a more balanced combination of hardness and flexibility.

That said, the phrase “graphene ceramic coating” does not guarantee premium performance by itself. Product quality still depends on formulation, application method, curing conditions, and surface preparation. A well-applied high-quality ceramic coating can outperform a poorly applied graphene ceramic coating.

For buyers and detailers, the best approach is to evaluate verified durability claims, maintenance requirements, and user results rather than relying only on branding language.

Challenges and Market Outlook

Despite growing interest, graphene coating still faces practical limitations:

- Cost: Advanced formulations can be more expensive than standard coatings.

- Performance variation: Not all graphene coating products use the same chemistry or quality standards.

- Application sensitivity: Surface prep and installation quality heavily affect results.

- Limited long-term field data in some sectors: Industrial and marine adoption requires proven durability over time.

Even with these challenges, the market outlook remains strong. As manufacturing improves and more products are validated in real conditions, graphene coating is likely to expand in automotive, industrial, electronics, and specialty protection applications.

The Future of Graphene Coating

The future of graphene coating will likely be driven by better hybrid formulations, more consistent production quality, and more realistic performance standards. Instead of hype-driven claims, the next stage of adoption will depend on measurable benefits such as longer service life, lower maintenance cost, and stronger resistance to environmental stress.

We can also expect broader experimentation in aerospace, marine, electronics, and infrastructure coatings where durability-to-weight ratio and corrosion resistance are critical. As application methods become more scalable and cost-effective, graphene coating may move from a premium niche to a more common protection option in high-value surfaces.

Final Thoughts

Graphene coating is one of the most interesting developments in modern surface protection, but it should be evaluated with clear expectations. The biggest value today comes from graphene-enhanced and hybrid coating systems that improve durability, water repellency, and maintenance performance in practical applications.

Whether you are considering a graphene coating for a vehicle, electronics, or industrial use, focus on formulation quality, application process, and real performance data. That is where the true difference is made.